5 things to consider when selecting your flange tags

To help you choose the right product for your operations, here are 5 things to consider when selecting your Flange Tags.

When it comes to keeping staff protected and ensuring pipework in high-risk workspaces is maintained in the appropriate manner, staying on top of critical procedures is vital.

It comes down to effective communication and efficiency amongst team members, which in turn maximises the safety for those operating and servicing hazardous environments.

Poor flange management can mean risk to human life or wellbeing, but can also cause major issues such as cost of downtime, environmental impacts, and a poor reputation.

In order to achieve such safety, though, the most important part comes with being aware of the process in place and knowing exactly what has already been carried out. This is where Flange Tags come in.

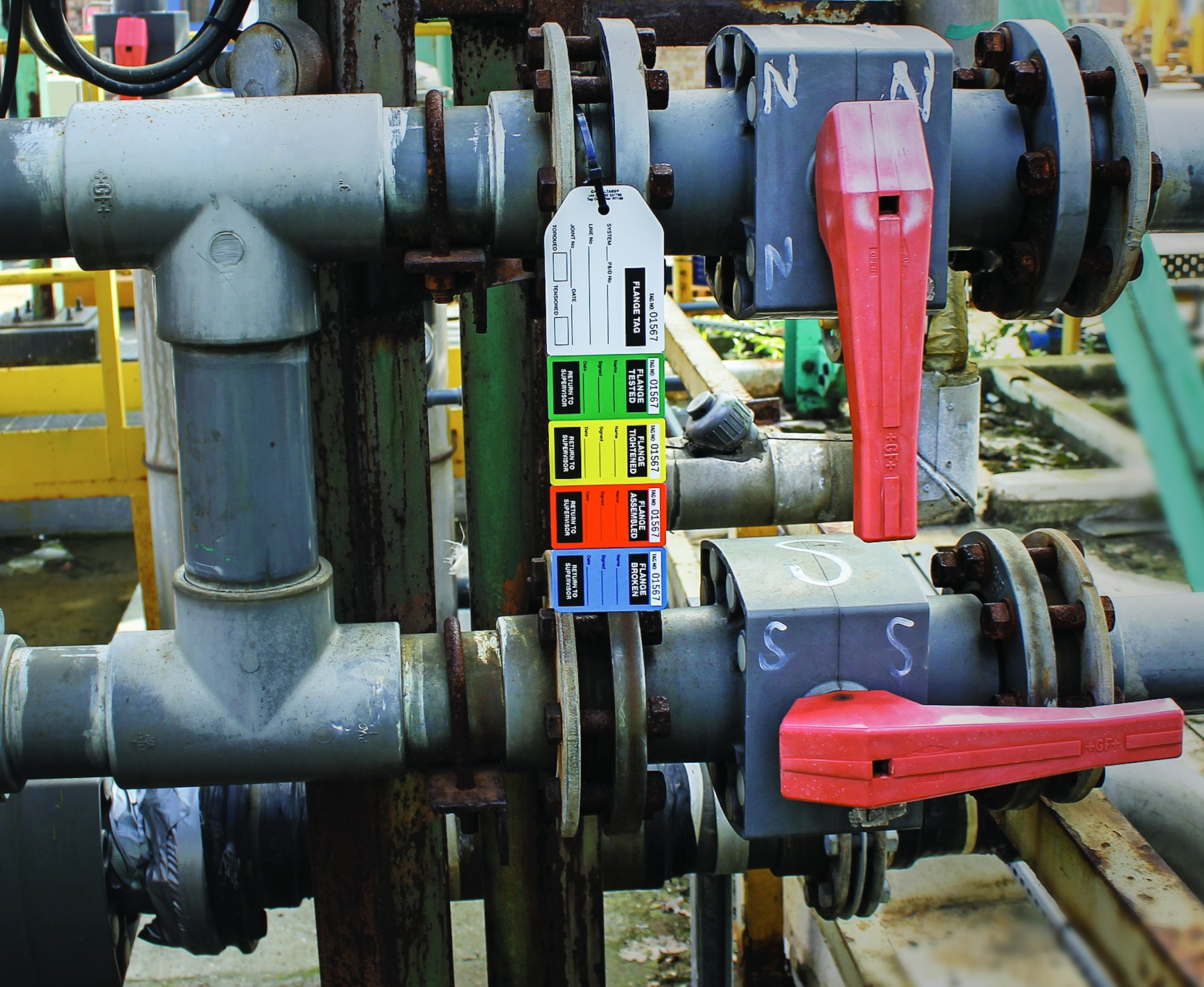

As a multi-part Process Management Tag, Flange Tags (torque tags) are used to communicate the current status of an inspection or management process through a highly visual record, one step at a time. They are attached at the beginning of a project and contain several sections, which are filled in and torn off each time a stage is complete

Sound simple, right? As much as Flange Tags are a straightforward concept, there can be many factors to your project that separate the reliable tags, from the not so reliable. So, to help you choose the right product for your operations, here are 5 things to consider when selecting your Flange Tags.

1. The importance of the process

The first thing to consider when selecting your Flange Tag should be how important the process is. To help identify this, think about what could happen if the process goes wrong. Could it cause an injury? Or even worse, be life threatening? If so, you’ll want to ensure the Flange Tag chosen for the process is not only strong and reliable, but simple to use.

2. The project duration

The next consideration to make when selecting your Flange Tags comes with the length of the project, so think about how long the Tag will need to be in service for. Both the material and thickness of the material used to create the Flange Tag will directly affect how long it can last, and in which conditions. Whether it’s going to be in direct sunlight or freezing cold temperatures 24/7, you’ll want peace of mind that your Flange Tag will not fail.

At REGALTAG, we supply UV and freeze resistant Flange Tags to companies all over the globe. Our multi-part tags are made from Prism polypropylene and provide everything you need to safely record all steps of the flange break process. We've also tried and tested our multi-part tags to ensure the tear-off sections are tough enough to stay intact in windy conditions, but still can be removed by hand when required. If you’re looking for a fully customisable Flange Tag solution to fit seamlessly with your existing processes, then get in touch with our expert team today – we’re always happy to help.

3. Number of stages in the process

Another important point to think about when selecting your Flange Tags falls on the number of stages the process has. If the process is complex and consists of many stages, you’ll need a tag that has enough sections to guarantee all stages of the process are met.

It’s also important to consider how you will keep a record of your maintenance process. Keeping these individual tag sections in storage provides a perfect solution as they provide a physical audit trail which is clear to review. Get in touch for help on setting up a system to store your Flange Tags.

4. Make the process fail-proof

When dealing with such high-risk processes, mix-ups and mistakes simply can’t be made. The effects can be detrimental. In order to avoid this, you want to look for Flange Tags that offer a wide range of unique colours and designs that don’t get easily confused with other multi-part tags. This helps to create an almost ‘fail-proof’ tagging solution.

With REGALTAG, not only do we offer completely customisable Flange Tags, but have a library of tried and tested designs to work from. This ensure your new tagging solution is easily identifiable and fits right into your process without the risk of mix-ups.

5. Improve process efficiency

Moving towards the topic of process efficiency, you may want to consider the integration of technology for your Flange Tags. By adding QR codes/ barcodes allows tags to be used with technology, like inspection software, which makes recording of information faster and more accurate. With this increased speed and accuracy, Flange Tags can in fact save your business time and money.

Another important feature to include is sequential numbering as this provides traceability and prevents duplication by making every tag unique. At REGALTAG, we keep records of all sequential numbering used to managed companies joint integrity Tags worldwide. Get in touch to find out more about how we can improve the efficiencies of your Tagging processes with our VARiTAG® technology!

Flange Tags from REGALTAG

Are you looking for a Flange Tag solution that you can rely on? Do you need help with your critical operations? Then talk to our expert team today. With a library of over 12,000 tagging systems, experienced advisors, and in-house manufacturing, we can ensure a reliable and speedy service your business deserves.

Subscribe

Join 18,000+ others receiving our monthly updates. Free Tag insights delivered straight to your inbox.