The crucial role of flange management in preventing leaks

In high-pressure industries, even a minor leak can lead to major consequences. That’s why flange management is essential, not just for maintenance, but for safety, compliance, and operational reliability.

In high-pressure industrial environments, even the smallest leak can lead to major consequences. From safety hazards and environmental damage to costly downtime and equipment failure, flange leaks are a risk no operation can afford to ignore. That is where flange management comes in. This is a critical process designed to ensure the integrity, safety and efficiency of bolted flange joints.

Flange management isn’t just best practice; it is an essential part of responsible operations. By implementing proper alignment procedures, following torque and assembly standards, and conducting regular inspections, businesses can significantly reduce the risk of leaks and extend the lifespan of their equipment.

In this blog, we will explore the key elements of effective flange management, common causes of flange leaks and the wide-ranging benefits of adopting a proactive approach. Whether you are in oil and gas, chemical processing or power generation, understanding the importance of flange management is a step toward safer, more reliable operations.

What is flange management and why it matters

Flange management is the process of ensuring the correct assembly, maintenance and inspection of bolted flange joints. These are the critical connection points in piping systems that are often exposed to high pressure, extreme temperatures and corrosive substances.

At its core, flange management is about leak prevention, operational safety and asset longevity. It involves a range of practices such as:

- Proper alignment of flange faces

- Correct bolt tightening sequences and torque values

- Use of appropriate gaskets and materials

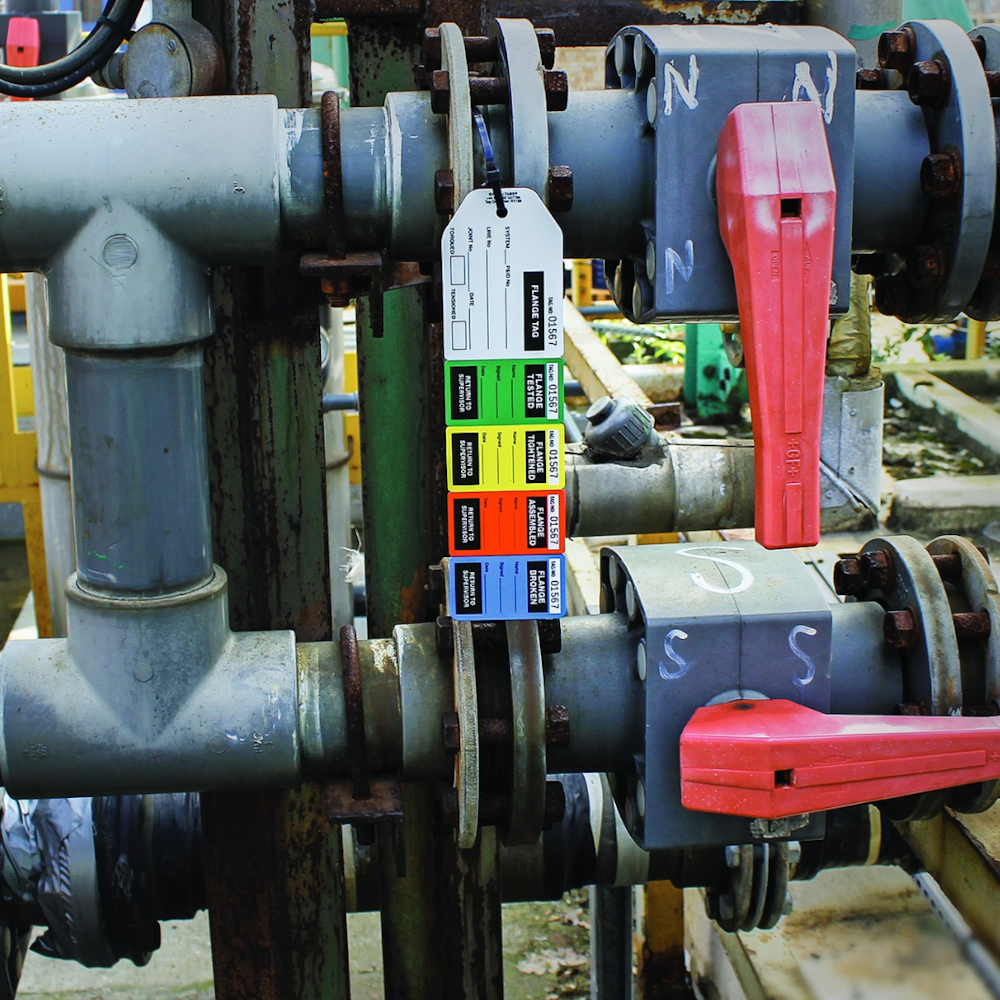

- Detailed documentation and tagging of each flange joint

- Routine inspection and integrity monitoring

When performed correctly, flange management helps ensure that every joint performs as intended under operation conditions, without leaks, failures or unexpected downtime.

Why flange management matters

1. Leak prevention

Leaks in flange joints may seem minor at first but they can rapidly escalate into severe safety, environmental and financial risks. Especially in industries dealing with flammable, toxic or high-pressure substances, a single leak can cause catastrophic incidents.

2. Safety compliance

Many regulatory bodies mandate regular inspection and maintenance of pressurised systems. A robust flange management system helps organisations meet compliance standards.

3. Extended equipment life

Improperly installed or maintained flange joints can lead to accelerated wear, corrosion and fatigue, reducing the lifespan of pipelines and connected components. Flange management helps preserve asset integrity.

4. Reduced downtime and costs

Reactive maintenance due to flange failures often leads to unplanned shutdowns. Proactive flange management reduces these interruptions and the high costs associated with emergency repairs.

5. Improved documentation and traceability

A formalised flange management system often includes digital tracking of flange conditions, torque settings and maintenance records. This improves transparency and supports decision-making during turnarounds or audits.

In short, flange management is not just a maintenance task, it is a strategic pillar of safe and efficient industrial operations. By investing in the right tools, training and procedures, businesses can safeguard their operations against preventable leaks and ensure long-term performance.

The high cost of flange leaks: Safety, downtime and repairs

Flange leaks are more than just a maintenance nuisance, they come with serious consequences that impact safety, productivity and your bottom line. Whether you are operating in oil and gas, chemical processing or power generation, even a minor leak can quickly escalate into a major issue.

1. Safety risks

Flange leaks often release hazardous substances, which can lead to fires, explosions, toxic exposures or environmental contamination. Workers near leaking flanges are at direct risk, especially when dealing with high-pressure or high-temperature systems.

In regulated industries, a single leak can trigger safety audits, fines or shutdowns due to non-compliance with health and safety standards.

2. Costly downtime

When a leak is detected, production often has to be slowed or stopped entirely to address the issue. This unplanned downtime disrupts operations, delays output and ultimately reduces profitability.

Depending on the severity, downtime from a single flange leak can cost thousands, if not millions, in lost productivity.

3. Expensive repairs and replacements

Repairing a flange leak is rarely a quick fix. It often requires isolating the system, depressurising, disassembling components and replacing gaskets or bolts. If damage is extensive, entire sections of piping or equipment may need to be replaced. Add in labour costs and emergency callouts, and the total repair bill climbs fast.

Common causes of flange leaks you need to know

Understanding the root causes of flange leaks is essential for prevention. While materials and design play a role, most leaks are traced back to installation or maintenance issues. Some of the most common causes include:

- Improper bolt tightening

- Poor flange alignment

- Damaged or incompatible gaskets

- Thermal cycling and vibration

- Corrosion or mechanical wear

Identifying these issues early allows for corrective action before a leak occurs.

The importance of proper flange alignment and assembly

Preventing flange leaks starts well before the system is pressurised, it begins with proper alignment and assembly. Even the most advanced sealing materials and robust flange designs can fail if they are not installed correctly.

- Misalignment increases leak risk: When flanges are not perfectly aligned, uneven stress is placed on the gasket and bolts. This leads to gaps, distortion and weak points where leaks can form.

- Gasket integrity depends on proper seating: The gasket is designed to create a tight seal between flange faces, but this only works if the surfaces are parallel and clean. Improper assembly can crush or misplace the gasket, compromising the seal from day one.

- Structural stress and long-term damage: Incorrect assembly not only causes immediate leak risks but can also introduce long-term stress into the piping system. This can lead to flange warping, bolt fatigue or even cracks in the pipe or flange neck.

- Standardised procedures matter: Following established procedures ensures a consistent, reliable seal. Training and certification for maintenance teams go a long way toward avoiding costly mistakes during installation.

Establishing a regular inspection and maintenance schedule

Flange integrity isn’t a one-time concern, it requires ongoing attention. A structured inspection and maintenance schedule helps detect early warning signs of wear, misalignment or stress-related damage.

Best practices include:

- Routine visual inspections to spot corrosion, gasket extrusion or bolt loosening.

- Torque checks to ensure fasteners remain properly tensioned.

- Ultrasonic or infrared testing for detecting leaks that aren’t visible to the eye.

- Documentation and tracking of flange performance, repair history and replacement intervals.

A proactive maintenance schedule reduces unplanned downtime, improves system reliability and supports compliance with industry regulations.

Key benefits of effective flange management

A strong flange management programme offers several benefits that directly impact safety, productivity and cost savings:

- Reduced leak incidents

- Enhanced safety

- Operational efficiency

- Lower maintenance costs

- Regulatory compliance

In short, flange management is not just a maintenance task, it is a strategic investment in the long-term reliability of your operation.

Adopting flange management protocols: A critical step forward

As industries continue to demand higher safety standards, greater efficiency and reduced downtime, adopting a structured flange management protocol is no longer optional, it is essential. From minimising leaks to ensuring regulatory compliance, a well-implemented flange strategy plays a pivotal role in overall reliability.

Putting the right protocols in place requires more than just good intentions. It demands the right tools, documentation systems and support to ensure consistency and accountability across every flange connection.

That is where REGALTAG comes in. Our flange tagging and inspection solutions help you streamline your maintenance workflows, improve traceability and ensure every flange is assembled, inspected and documented to the highest standards. With robust, field-proven tagging systems and digital tracking options, REGALTAG gives you the confidence to prevent leaks before they happen.

Subscribe

Join 18,000+ others receiving our monthly updates. Free Tag insights delivered straight to your inbox.