Training staff to properly use and understand inspection tags

Inspection tags are essential for workplace safety, compliance, and communication, but they’re only effective when your team knows how to use them properly. Without the right training, even the best tagging system can fail, leading to costly mistakes and serious safety risks.

Inspection tags play a vital role in maintaining workplace safety, ensuring regulatory compliance and facilitating clear communication across teams. But even the most robust tagging system is only effective when the people using it understand how it works and why it matters.

Without proper training, inspection tags can be misread, misused or ignored altogether, leading to costly mistakes, safety incidents and compliance failures. That’s why investing in staff training is just as important as choosing the right tags.

In this blog, we will explore the risks of untrained personnel, the benefits of consistent training across shifts and the essential components of a strong inspection tag training programme. Because ultimately, the reliability of your tagging system comes down to the knowledge and accountability of the people behind it.

Why inspection tags are crucial for safety, compliance and communication

Inspection tags are more than just labels, they’re frontline tools that help create a safer, more organised and legally compliant workplace. When used correctly, they provide a clear, visual indication of equipment status, maintenance history and any potential hazards. This real-time communication is essential in fast-paced or high-risk environments where delays or misunderstandings can have serious consequences.

- From a safety standpoint, inspection tags help prevent accidents by signaling whether equipment is safe to use or requires attention.

- In terms of regulatory compliance, inspection tags support adherence to industry standards and legal requirements.

- When it comes to communication, inspection tags act as a universal language across departments and shifts. They eliminate ambiguity by providing consistent information about the condition and status of assets.

In short, inspection tags are critical components of a proactive safety culture. But without proper training, even the best tagging system can fall apart. That’s why the next step, equipping your staff with the knowledge and skills to use inspection tags effectively, is key.

A tagging system is only as good as the people using it

Even the most advanced or well-designed tagging system can fall apart without properly trained staff behind it. Inspection tags are only effective when the people reading, applying and responding to them understand what they mean and why they matter.

You can invest in durable materials, colour-coded designs and automated tracking systems, but if workers misinterpret a tag or ignore its significance, the system fails. This not only puts safety at risk but also undermines compliance efforts and damages team communication.

Here’s why proper training makes all the difference:

- Reduces human error: Trained staff are less likely to misread or overlook important tag information.

- Builds consistency across teams and shifts: Everyone applies and interprets inspection tags the same way, no matter when they’re working.

- Improves response time: When employees recognise the urgency or importance of certain tags, they can act faster to resolve issues.

- Reinforces responsibility: Staff are more likely to take ownership of safety and maintenance protocols when they understand their role in the tagging process.

- Supports ongoing compliance: Trained personnel ensure that tagging practices align with industry standards and inspection requirements.

Ultimately, your tagging system is only as reliable as the people using it. That’s why training isn’t optional, it’s essential.

The risks of untrained staff: Mistakes that can cost

When staff aren’t properly trained to use inspection tags, the consequences can be serious, both in terms of safety and business operations. What may seem like a small oversight can quickly lead to costly mistakes, regulatory breaches or even workplace accidents.

Here are some of the most common risks associated with untrained personnel:

- Misinterpretation of tags: Without a clear understanding of tag meanings, employees may mistakenly assume equipment is safe to use when it’s not.

- Missed or skipped inspections: Staff who don’t understand the importance of tagging procedures may fail to carry out inspections properly or at all, allowing faults to go unnoticed.

- Safety failures and injuries: In high-risk environments, ignoring or misunderstanding a warning tag can lead to serious injury, damage to equipment or worse.

- Regulatory non-compliance: Many industries are subject to strict inspection and documentation requirements. If tagging systems are not used correctly, your business may fail audits, incur fines or face legal action.

- Breakdown in communication: Untrained staff may remove tags prematurely, apply them incorrectly or fail to report issues. This can lead to confusion across shifts and teams.

- Damage to reputation and operations: A single avoidable incident caused by tag misuse can affect customer trust, slow productivity and increase operational costs due to investigations or downtime.

Failing to train staff on inspection tags doesn’t just put people at risk, it puts your entire operation in jeopardy.

Key elements of effective inspection tag training

To get the most out of your inspection tagging system, staff training must be clear, consistent and practical. It is not enough to simply explain what the tags are, you need to ensure every employee knows how to interpret them, apply them correctly and follow through with the necessary actions.

Here are the key elements of an effective inspection tag training programme:

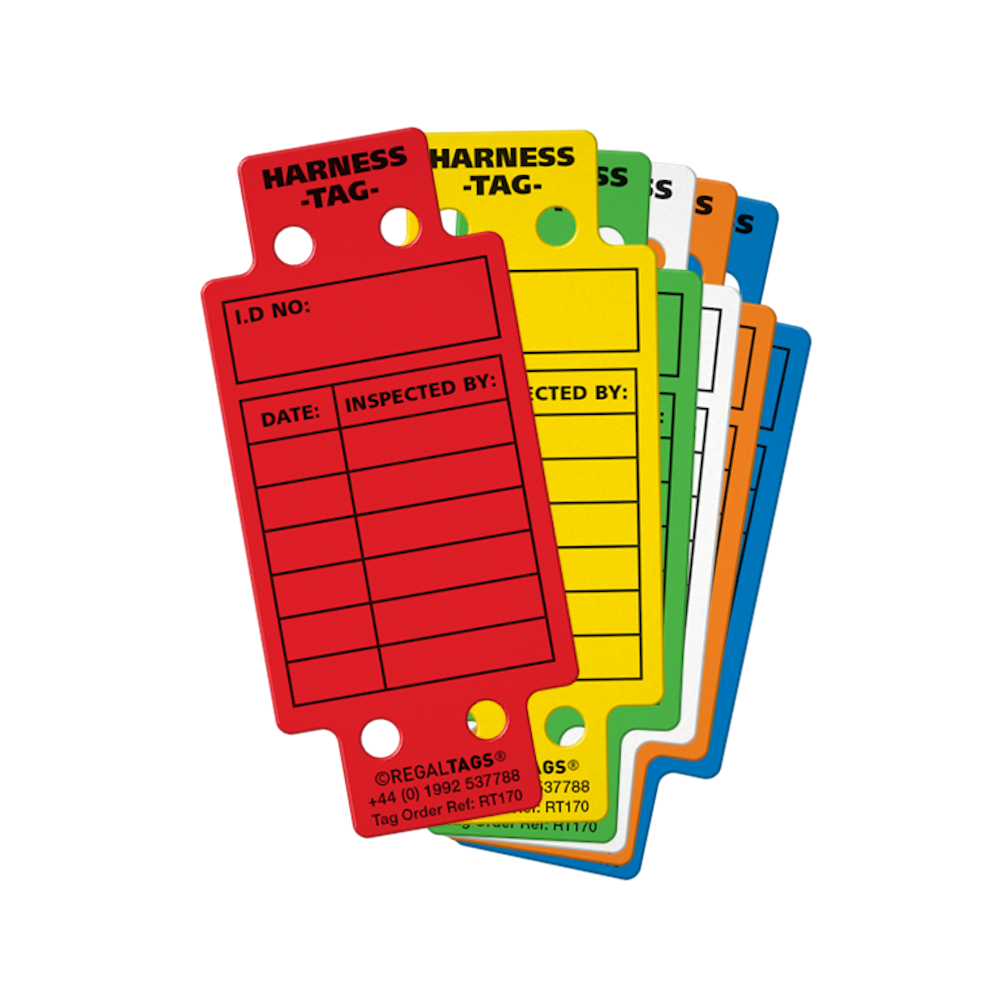

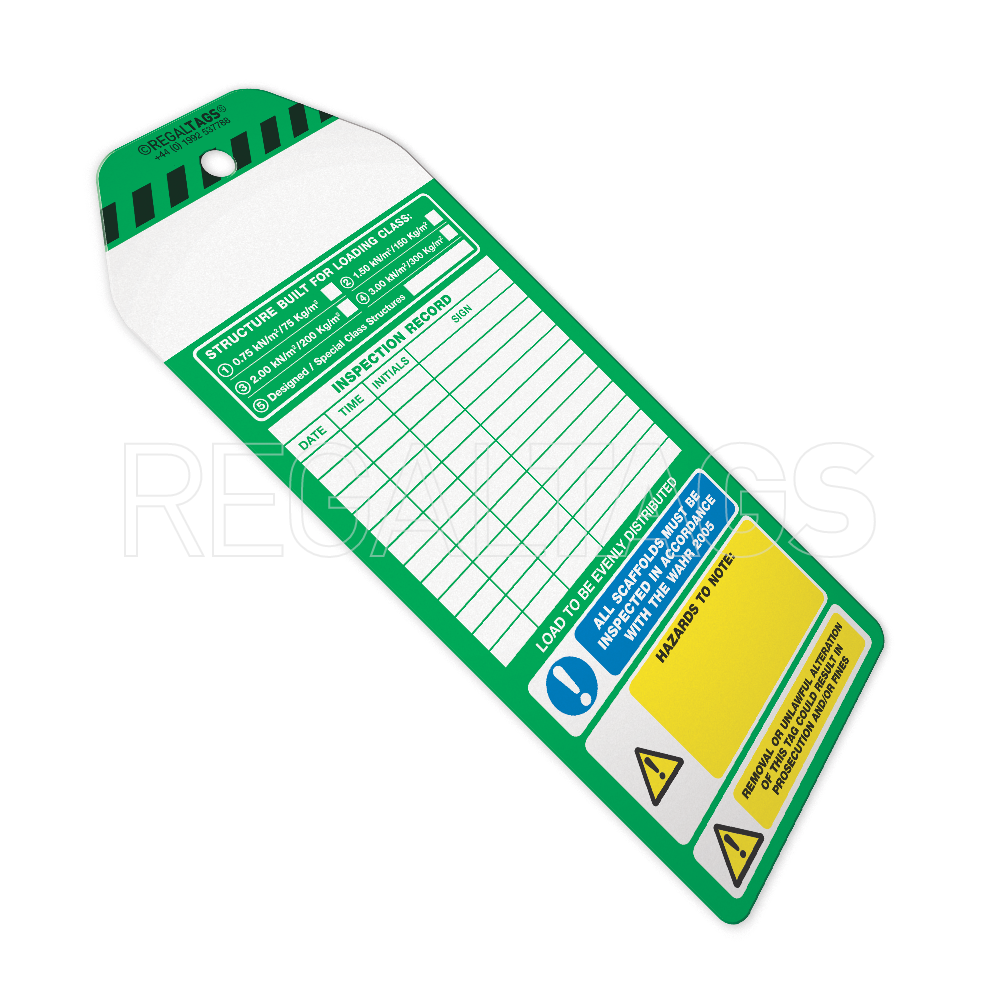

- Understanding tag types: Staff should be familiar with the different types of inspection tags used in your workplace. Whether they indicate inspection status, equipment faults, maintenance schedules or lockout/tagout procedures. Understanding the purpose of each tag is the foundation of correct usage.

- Decoding tag information: Employees need to know how to read and interpret the information on a tag. This includes understanding colour codes, symbols, dates, initials, inspection notes and any regulatory references. Consistency in interpretation across teams is critical to avoid miscommunication.

- Practical tag application: Training should include hands-on practice in applying and removing tags correctly. This covers where to place tags, how to secure them and when they should be removed or replaced. Mistakes in application can lead to overlooked hazards or invalid inspections.

- Compliance awareness: Staff must understand how tagging ties into legal and regulatory requirements. This includes knowing which records must be kept, how often inspections should occur, and the role inspection tags play in audits or workplace investigations.

- Reporting procedures: Finally, employees should know what to do when they encounter a tag, whether it’s reporting a problem, escalating an issue or logging completed inspections. Clear reporting channels help ensure accountability and traceability throughout the process.

By covering these essential components, your training programme will not only teach your staff how to use inspection tags but also help them understand why it matters. This builds a stronger safety culture and ensures your tagging system is reliable, every step of the way.

The payoff: Safer workplaces, smoother operations

When your staff are properly trained in inspection tag procedures, the impact goes far beyond compliance, it creates a safer, more efficient and more trustworthy workplace.

Here’s what you gain when everyone knows how to use inspection tags correctly:

- A stronger safety culture

- Greater accountability

- Reduced downtime

- Fewer compliance breaches

- Enhanced trust between management and workforce

Proper inspection tag training is a smart investment in the long-term health of your business. With knowledgeable, confident employees, you will build a tagging system that truly works and a workplace culture that prioritises safety, accountability and success.

Invest in training and in durable tags that work

A safe and efficient tagging system depends on two things:

- Well-trained people

- High-quality tags

One without the other simply isn’t enough.

While training equips your team with the knowledge to use tags correctly, durable, reliable inspection tags ensure that critical information stays visible, legible and secure, no matter the environment. Whether you are dealing with harsh weather, heavy machinery or fast-paced operations, your tags need to hold up under pressure.

That’s where REGALTAG comes in.

Our inspection tags are built for performance, engineered to withstand tough conditions while maintaining clarity and compliance. From colour-coded inspection tags to custom solutions for unique workflows, we provide the tools that make tagging systems more effective.

Pair that with a strong internal training programme, and you have a complete solution that supports:

- Workplace safety

- Operational efficiency

- Regulatory compliance

- Team accountability

Don’t let poor tagging or lack of training put your business at risk. Invest in both and see the difference it makes.

Explore our full range of inspection tags and take the first step toward a safer, smarter workplace.

Subscribe

Join 18,000+ others receiving our monthly updates. Free Tag insights delivered straight to your inbox.